New to Catarafts? This page can help

This is a discussion for those new to the use of inflatable pontoons. Here we will discuss what makes them work, and some different frame options. These ideas work for a variety of uses, and are not limited to these materials. For instance, If you are in the tropics, you could consider using bamboo instead of metal. Russians have been using small trees to build frames on site for years.

Large Cataraft proposal for Gold dredging on the Yukon Delta

This document assumes that the customer has little knowledge of how inflatable cataraft pontoons work. The author of this document has limited knowledge of how gold dredging works. However we have made pontoons for many different gold dredging operations over the years in both Alaska, and in California. Therefore it is up to the customer to use the pontoons to float the equipment that he is knowledgeable about, and make it work. This document shows some of our experiences with different products.

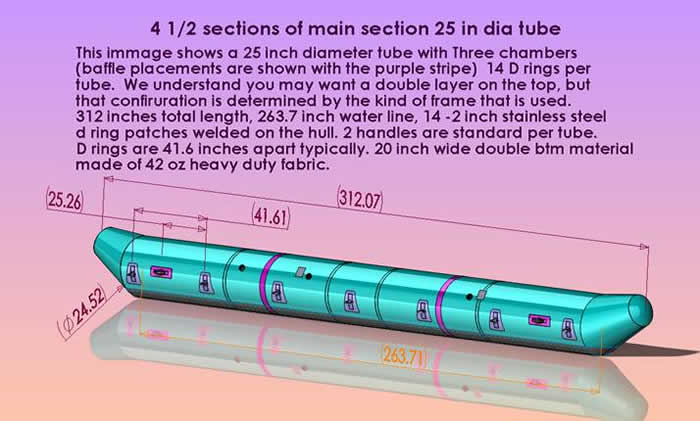

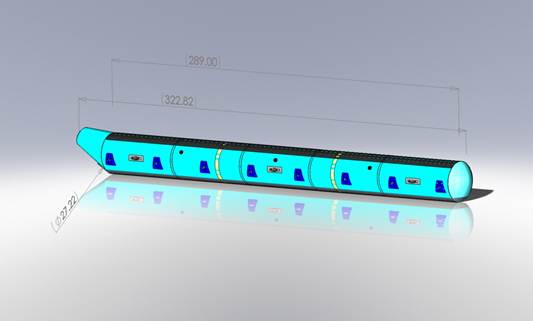

First is the style of pontoon being considered. The length of the frame being considered is 22 ft (264 inches)Between the cones on this unit is 263.7 inches, This is an economic length because It is built with 4 ½ sections of inflatable fabric. 5 sections would be 289 inches.

These pontoons can come with a variety of cone configurations. They can be pointed or blunted like the photo above. They can have a symmetrical shape like the tip of a pencil, or an asymmetrical shape like the one above. They can have a curved shape on the front, with a blunt or pointed shape. Usually the asymmetrical cone shape has a rounded end (We call it blunt.). Our customers find this more pleasing to the eye, and it has an advantage of shorter overall length for the same cargo capacity.

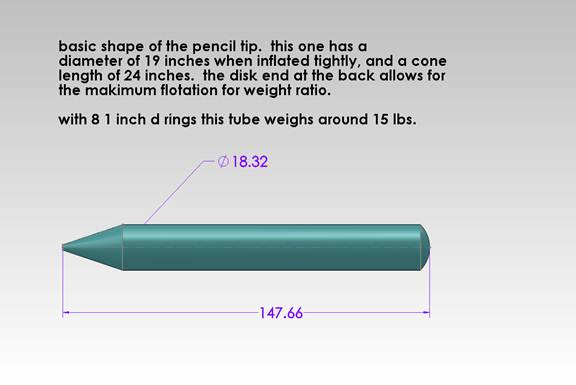

This is the same cone configuration as the first picture, but with pointed tubes, and less than half the overall length. The tubes in the picture above are known as asymetrical cones, ecause the center line of the cone is not the same as the axis of the main part of the tube. The picture below shows a pencil tip tube that is symetrical because the axis of the cone and the axis of the main tube are colinear or are on the same line.

This is the shape of a pencil tip cone with a disk end on the back. The advantage of the disk end is to have even more flotation of the main tube with even less length. Advantage of the pencil tip is slightly more hull speed, and the cone is out of the way

A curved tube with a blunted pencil tip on one end, and a blunted curved tube on the other.

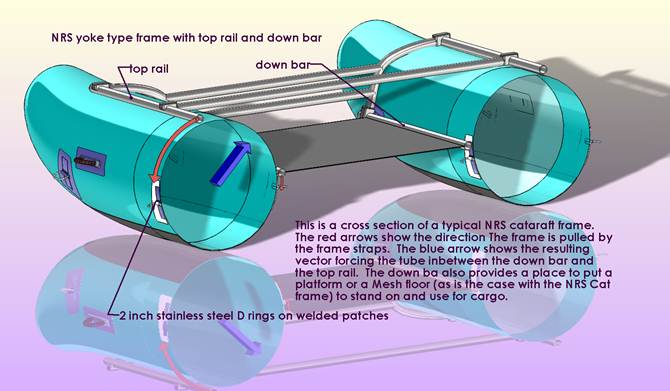

Frame styles:

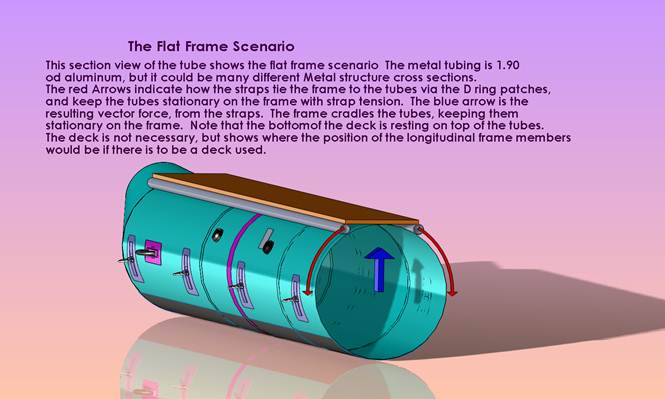

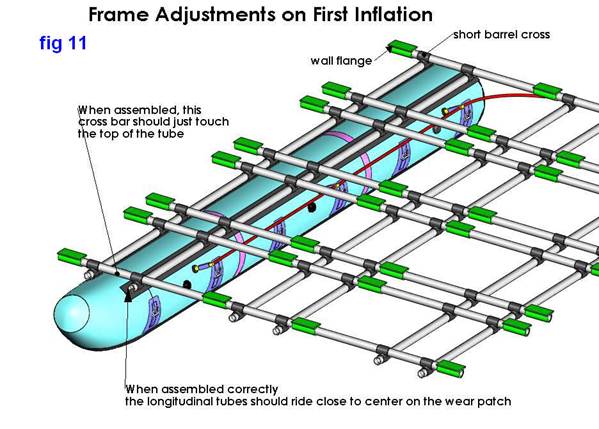

We do not assume to know how gold dredging equipment or many other kinds of scientific equipment is used. One customer who dredges on the Yukon River delta used aluminum ladders for the frame members on his tubes. That seemed to work ok for him, but our experience is in whitewater, and we use ideas that help keep the frame stable on the tubes. These ideas should function for the same reason.

At this point it is important to note that the style of frame will determine what kind of top chafe you will put on if any. We find that if customers are careful on how they rig and de rig their boats, that the top chafe may not be necessary. For instance, rope under a frame and tight on the tube will wear off the coating. However straps will not because they have more surface area. Also most strap wear comes from pulling a dry strap out from under the frame and burning off the coating with heat of friction on that spot where the strap contacts the tube and the frame.

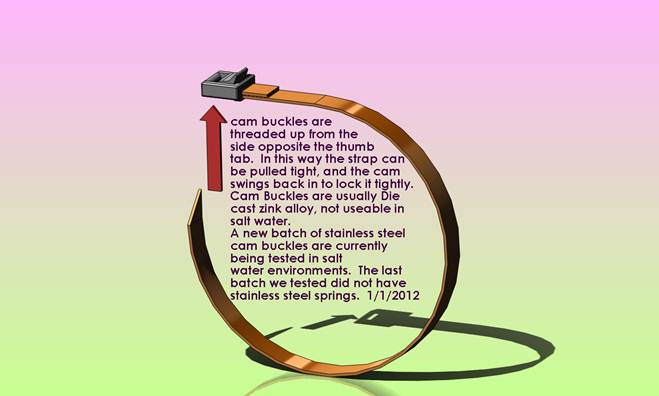

Also knowing that the tubes may be used in a salt water environment is an issue when using some metal buckles.

In salt water environments we have often recommended using double D ring cinches with stainless steel d rings. One will need to tie a loop near the cinch to help keep it from slipping, but this has been effective for research cats we sold to NOAA.

This system is used as a sea hoist by NOAA in Hawaii. Note the A frame set up. At a later date they reinforced the A frame cross member by welding aluminum bar stock on the bottom so they could lift more weight.

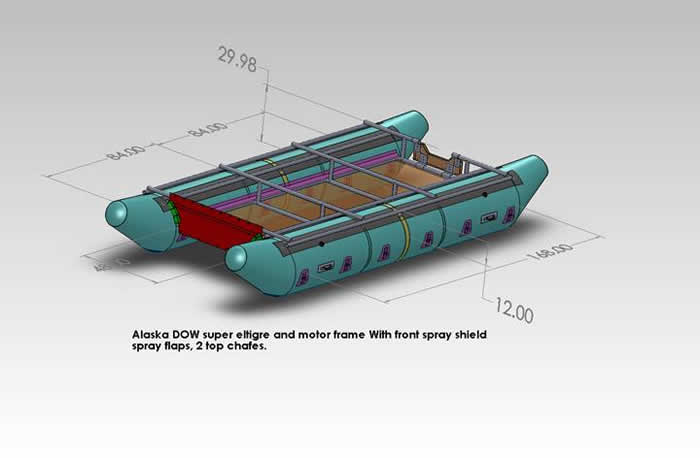

Below is a solid works drawing of a cataraft system that we made for the Alaska dept of wildlife.

This system has the double top rail and a down bar along the inside of the tube. It has a transom for a 40 hp gasoline motor. Along the inside you can see through the floor where the 2 inch stainless steel D ring patches are located. There is also a heavy fabric layer that folds over the top of the floor and this helps keep splash from coming up over the floor board in a big way. There is also a spray shield on the front to help keep spray from entering the cargo/passenger compartment. Note that there are 2 top chafe pieces on the top. This frame was manufactured by Riverboat works in Salida Co.

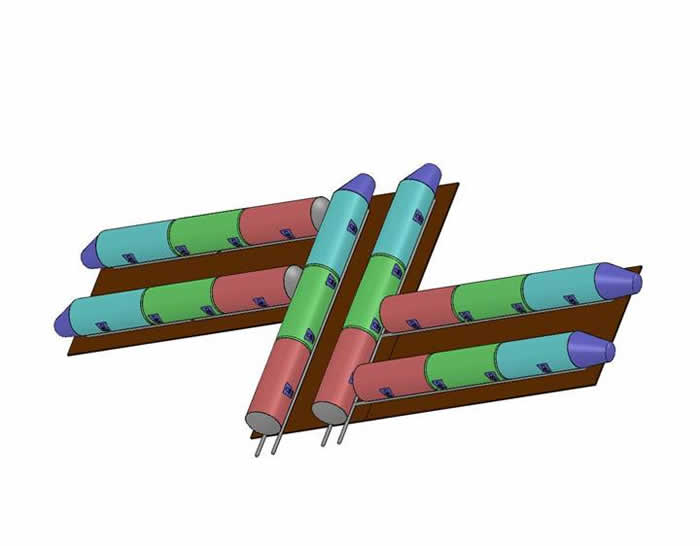

This image is a bottom view of a floating dock type platform that is easily dismantled and stored. The system uses 1.90 inch aluminum tubing, with flange fittings. The flange fittings allow the deck to be bolted thru the flanges. This system was used in a trade show environment where participants were encouraged to paddle canoes up to the platform and participate in various activities with a crowd of peers on shore watching.

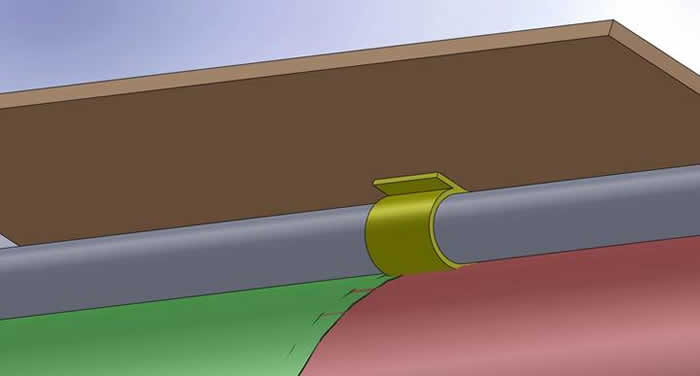

This immage shows a detail of the flange in yellow. They actually have holes that allow you to bolt to the decking.

We used a similar concept in an inflatable sled device in Antarctica. Unfortunately the -40 cold crack on the PVC tubes was not enough so we went to another design with out the frame for Greenland. As far as we know the frame held up well.

One final frame concept is the one that wraps around the tubes in an arc as this frame does. This kind requires careful design to make sure the tubes work with frame.

O

Here are some other gold dredge ideas

These tubes were used to make a big set of dredge tubes. They are dwarfed by the large boats in the next picture.

Here are some smaller portable dredge units we made tubes for a few years ago.

We appreciate you takin the time to read up on some of the issues involved in making inflatable pontoon systems. There is a whole lot more infromtion about any one of these immages, so it this sparks any creative ideas, drop us an email at the adresses below, and we will be happy to correspond with you. The best bet is the info adress.

home | products | pictures & information | find a dealer | river stories & testimonials | related info | FAQ | contact us

Order inquiries: shop.jpwinc@gmail.com

Custom & Prototype inquiries: pschoser.jpwinc@gmail.com

© 2011 Jack's Plastic Welding, Inc

Toll Free 1-800-742-1904

P. 505-334-8748, F. 505-334-1901