Custom Dry Bags- JPW book of standard designs

Introduction:

I did an extensive document about paco pads. This time I want to do a document about Dry bags. This document is tied to the customizing of dry bags. With this document, we will be able to do custom dry bags without doing new drawings all the time. The purpose is to get customers and staff to use the same terms, and the same images. This will enable customers take measurements for a custom dry bag that will work for them.

Before reading this document, we suggest that you quickly look over these three web sites. Just to know where you should go next after you decide you need a custom dry bag.

Designing a custom dry bag that will fit your item.

See the custom bag table chart

See the accessories price list for some of the more common accessories we use. Others will need quotation.

Please Note that the terms used in bold are the terms we use at the shop. When considering having us make a custom dry bag, using these terms will cut down on design time, and increase everyone’s understanding of the product.

Dry bag styles: These are general concepts of how we classify our dry bags, what the part names are, and why they are named the way they are.

General categories include: Round bottom Outfitter bags. Stow bags, rectangular bottom bags, Roll down duffel bags, Flat bottom bags, double ended duffel bags. Drop Bags, boat bags, motor bags, Everything bag, Mesh bags, Collapsible buckets, Zipper bags, Musical instrument bags, Stove Bags, rectangular bottom bags, oval bottom bags.

Closure adaptations: Grommet and hem, standard roll down, stow bag style, hard top vs. soft top, Roll down grommet closure, Double D ring Cinch, Cam buckles Vs. SR1 buckles.

Dry bag accessories include: grommet strips, d rings, channel closures, back pack straps, shoulder slings, daisy chains, inside pockets, and inflatable pockets.

Materials for dry bags: How to choose the best material for the right application:

Hatch River Expeditions still has dry bags that we made for them in 1983. It is now 2013, and that is 30 years later. What makes the Hatch bags last so long when they are being used in the outfitting industry? The secret is how they are transported on the river and in the truck back to the warehouse. Hatch puts their sleeping pads inside the bag, and this makes the bag protect the sleeping pad as well as the sleeping pad protecting the bag. They also put a tarp over them when on the river. This protects them from the customers and from the sun. It is possible to get many years of use out of a dry bag and pads if they are adequately protected in transport, and from the sun. Most of our customers would consider this practice impractical because our pads are water proof, and a pad inside a dry bag takes up valuable dry bag cargo room, but I think you see why it works. Whenever you put hard objects in a dry bag there is a danger that the dry bag material will wear on those hard points. You may put a heavy foam liner in the bag to protect the bag and the equipment. Is it cost effective? In the case of one customer in Canada, it cost a lot more money to ship the bag with the ethafoam liner, and the liner itself was bulky and hard to use. The customer ended up not using it. And the bag would have cost hundreds of dollars less in both design, manufacturing, and shipping cost If he and not used it.

When using different materials, consider that more plastic in the fabric means more money, and the more often a fabric is used for other things the less expensive it is. 42 oz. heavy fabric is ultra-tuff, and easily 4 times the cost of 18 oz. truck tarp fabric. Would it be worth putting a reinforcement patch on a potential wear spot? Or would it be better to make the main section (what we call the cargo area) out of 42 oz. material. How important is it to keep absolutely dry. A propane stove can still operate if it is wet. Is the purpose of the motor bag to keep the water out, or to keep the grease in, and is it really necessary to protect it from submersion? Ask yourself these hard questions before plunking down the money on the fanciest thing. Some options may not be necessary, and we can save you some money if you are willing to consider the options.

General categories of Dry Bags:

Outfitter bags: Have round bottoms regardless of the style of closure. The small bag on the left, is a stow bag. The closure clipping together at the top is what makes it a stow bag. So the one on the left is an outfitter stow bag. The rest are Round Bottom Outfitter bags, commonly called outfitter bags. From left to right our standard outfitter bag line is…. Outfitter stow, 1000 cu in or .6 cu ft., Small outfitter bag, 2.5 cu ft., Medium outfitter bag 3.5 Cu ft., and large outfitter bag 5.0 cu ft.

Figure 1

Standard features on outfitter bags include: a handle located near the center of mass for a fully loaded bag, welded Stainless steel D rings, a hard closure Each bag has PVC Coated nylon web that goes around the top, and this feature makes the bag more water tight because it is the place where the roll down squeezes the closure together. On all roll down bags there is a tab where this pvc web sticks out away from the bag. This tab of pvc coated web is where the strap is sewn. Stow bags do not have a tab because they have a soft top.

Hard top vs soft top: A hard top has a plastic strip welded in the closure, and is used for Roll down outfitter bags. A soft top has webbing welded in the top, and is used for the Stow bag style closure. However there are situations where we use a hard top in stow bag fashion, and it will be noted as such. For instance stow bag closure with hard top. This would indicate that a plastic strip is welded in the top, but the closure is made by rolling and clipping to the other side of the closure to make the same kind of handle looking closure that is on all stow bags. The SR1 or Cam buckle or double D ring cinch would be attached to the tab in the case of a stow bag closure with hard top.

Customized changes to outfitter bags include: Replacing the SR1 plastic side release buckles with cam buckles. Double D ring Cinch for salt water aplications, when Plastic buckles are not wanted. shoulder slings- where a 1 inch stainless steel D ring sewn at one side of the closure near the closure tab. In figure 1, the large red outfitter bag has this feature. Shoulder straps require a 3rd d ring patch welded near the top of the gear load. The channel closure system can have either cam buckles or a SR1 buckles. The channel closure does not cost as much as 2 d rings, and can get the buckle closer to the bottom of the bag for more roll down. We believe that they are not as durable because of the buckle location.

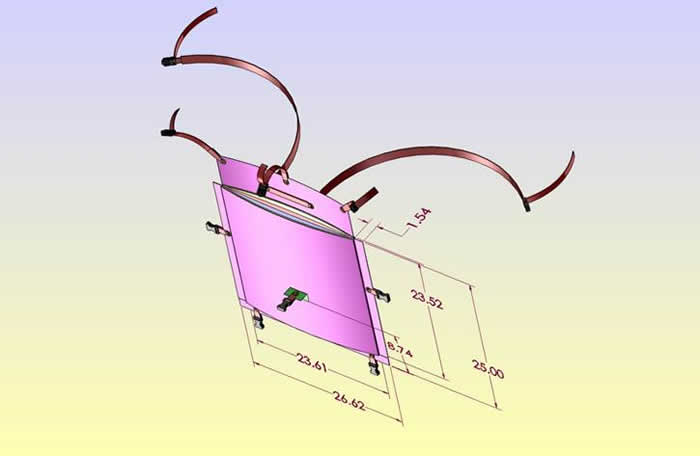

Figure 2 Removable back pack straps the d ring at the top is added to the system.

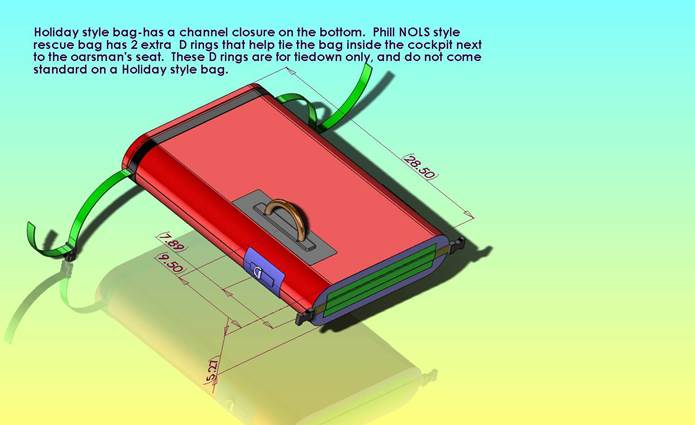

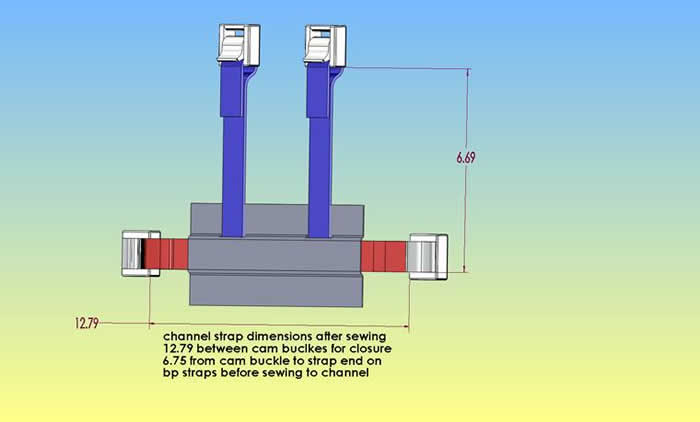

Figure 3 Channel closure system on the bottom with cam buckles replacing the SR1 plastic buckles

Figure 4

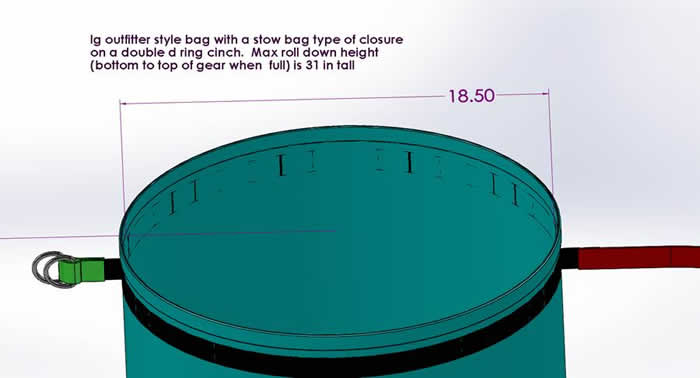

Example of a bag that has a hard top (plastic strip welded inside the closure) with a double d ring cinch on on side sewn to the tab, and a strap on the other side sewn to the tab. This is a large outfitter bag size stow bag closure style.

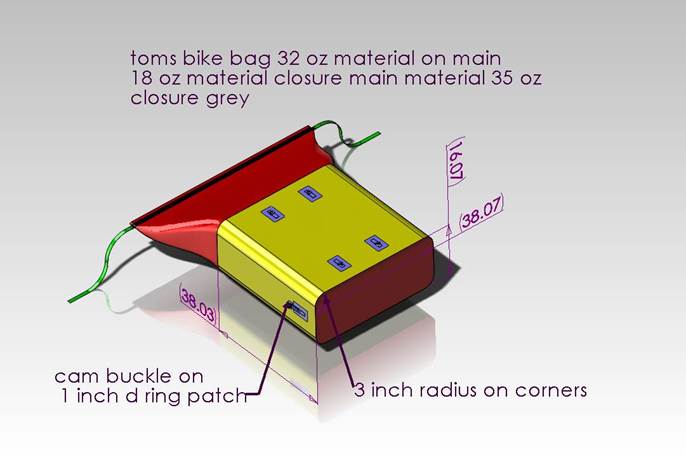

Oval bottom vs. rectangular bottom: It is easy to confuse these two bag types, but if a rectangular bottom cannot get any narrower than 6 inches. At that point the 3 inch radius on the edge will touch and become an oval. But oval may be used to describe a bag bottom that is much narrower than it is long.

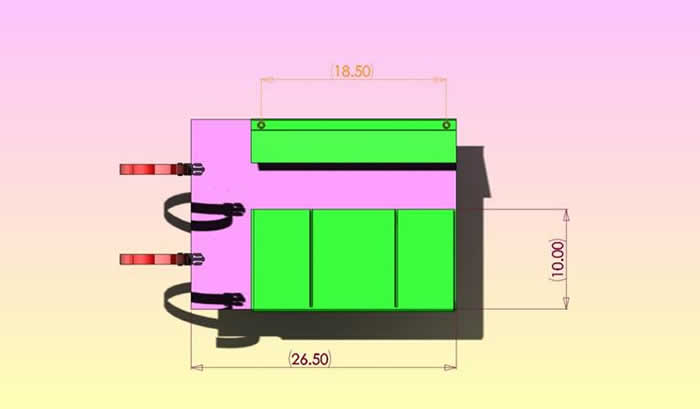

Figure 5 oval bottom with a channel on the bottom for the roll down closure

Rectangle RF welded bottom vs rectangular radius corner bottom:

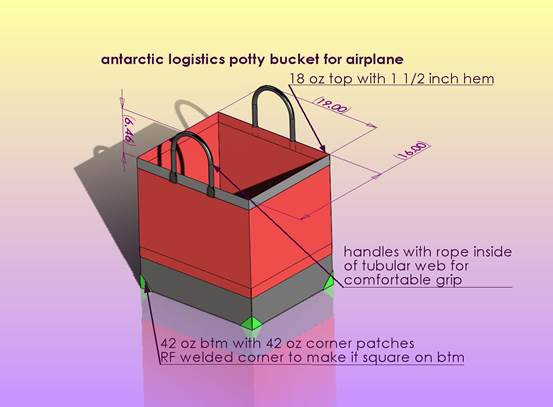

It is seldom that we need to make bag bottoms in a perfect rectangle shape. In the case of Antarctic logistics, we made the bottom perfectly rectangular, with heavy 42 oz. fabric, and even put extra corner reinforcements. The bag surrounded a potty in a plane that flew to Antarctica in rough air space, and the plane did not have a bathroom. This helped keep stuff where it belonged. Most all other rectangular bags have a 3 inch radius corner. They are less expensive to make, and have no corner to wear. We will always refer to rectangular bottom as a bottom with a 3 inch radius unless it is an RF welded rectangular bottom.

Figure 6 Perfect rectangle that is reinforced. Called an RFwelded rectangle bottom with reinforcements.

Figure 7 Radius bottom corners are the standard rectangular bottom. These are usually butt welded for accuracy.

Figure 8

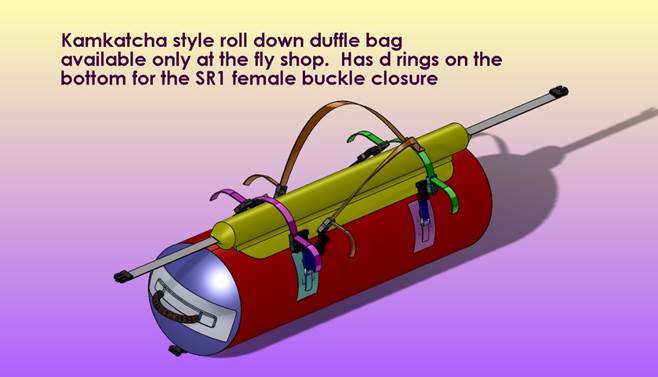

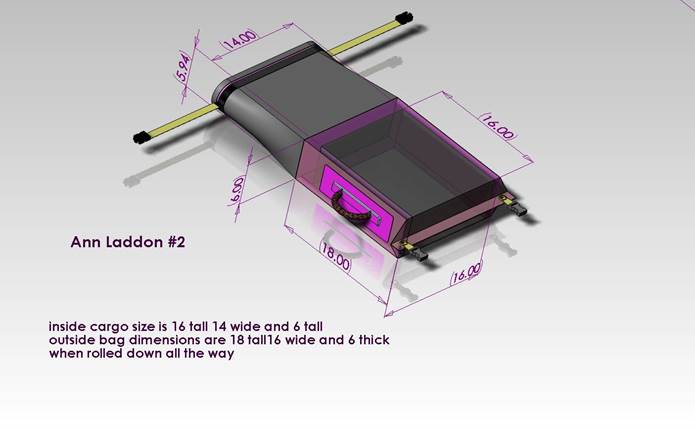

Roll down Duffle bags are bags that 2 round ends and the closure is on the side. This gives more access to gear inside, but not as easy to get water tight with the roll down.

Figure 9

The Kamkatcha style roll down duffel bag has loads of features including shoulder straps.

Figure 10

The double ended duffle bag has closures on each end. That is why it is called double ended. Customers sometimes say that when using our flat bags or our round bottom outfitter bags, the item you are looking for is always at the bottom. With closures at both ends there is no bottom. Ends are color coded so you can put some things in the green strap end, and other things in the red strap end. This bag makes a great back rest too, and some of our customers call it a back rest paddle bag, where your gear is right behind you to the right or to the left inside your back rest.

Flat bottom bags: Flat bottom bags can have a stow bag like top, can roll down, and can have a soft or a hard top closure. What distinguishes these bags from others is the way we seal the bottom. We use a skinny pass, and a flat seam pass weld to close the end in the exact same way that we close the ends of paco pads. Corner condoms may or may not be added, and bottom corner tabs may or may not be added. The image below shows a roll down system where the female SR1 buckle is sewn through a corner grommet. Making this bag a flat bottom bag with a roll down grommet closure and handle.

Figure 11

Flat bottom bag with roll down grommet closure

Drop bags:

Drop bags are named for the way they drop into a place in the frame were a cooler or an aluminum box would otherwise be. They are designed to be water proof containers for gear and food. They have rectangular bottoms, and are often used with something like a piece of ethafoam, (stiff closed cell foam) or plywood to stiffen up the bag. These are used in situations where it is desireable to reduce space for flying out gear at the take out. In Alaska for example.

Figure 12

Drop bag with fold over flap (a flap that is buckled over the closure at the top. In this case a stow bag style closure.0

The bag in this example has extra cam buckles at the bottom to suspend the bag from the raft frame.

Figure 13

The everything bag with a stow bag style closure and a fold over flap

The everything bag: This bag is commonly called an everything bag. It fits in the back of a raft, and will take on everything including propane tanks and dutch ovens if the bottom is protected with ethafoam. I suggest that dutch ovens legs be pressed into 2 inch thick ethafoam to protect the bottom of the bag. This system has worked for us in the past using outfitter bags.

Figure 14 Everything bag on the Grand

Figure 14 Everything bag on the Grand

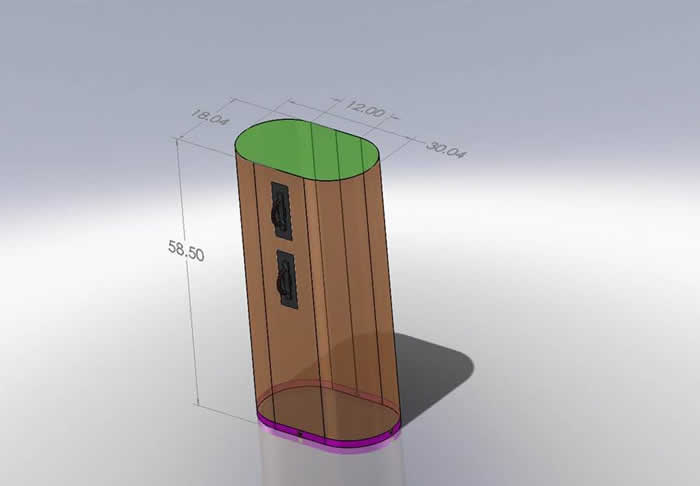

Boat Bags: boat bags can be flat bottom, or round bottom. On larger bags they come with handles to help people carry the boat inside the bag. Boat bags are distinguished by the fact that they have a hem and grommets in the end where the closure should be. They are not water proof. They should never be used to haul garbage. The flavor of garbage on raft tubes is irresistible to rodents, and that is the absolute worst damage a boat can sustain!

Motor Bags: Motor bags are very close in design to boat bags. They can also have flat bottoms, or round bottoms. This one has handles toward the bottom of the bag (note the bag is upside down) because the power head is near the bottom of the bag, and most of the weight is down at that end.

Figure 15 Motor bags and boat bags are similar, but may have handles in different locations this bag is for a 20 hp Tahatso motor.

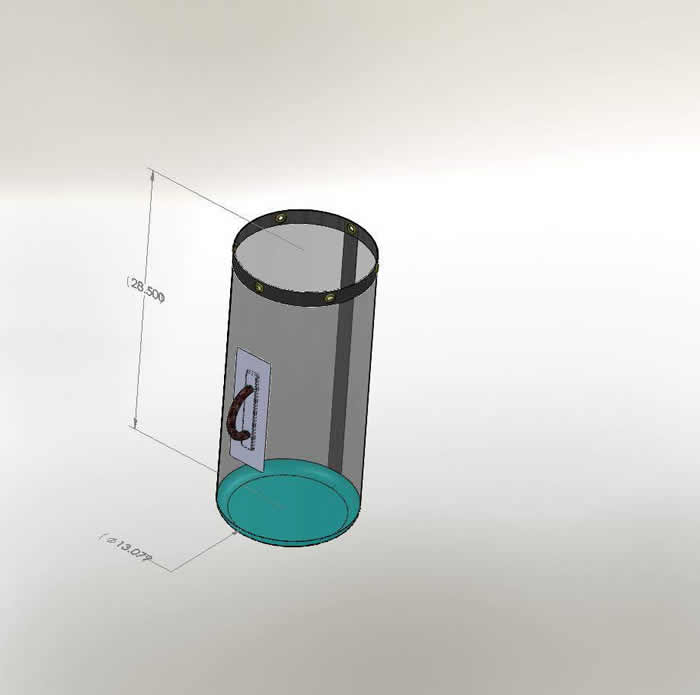

Mesh bags: Mesh Bags are obviously made of mesh. We use superman mesh, and most often weld it to a round bottom that is made of 30 + weight fabric. There has been times when we made bags with the mesh in the bottom. Mesh bags are used for produce, crushed cans, Drinks, drag bags, and for anchors when you put rocks in them. On river trips the idea of using mesh bags for hard vegatables and fruit has been proven many times. Boatmen/ women can place the mesh bag in the river at nite and cool these items down and at the same time rinse any mold spores off. It works the same way for your favorite beverage.

Figure 16 large mesh bag concept

Figure 17 large mesh bag used to store canned beverages. In this example, there is a cam strap laced through the grommet and hem system at the top. It is used like a draw string to close the top of the bag. The same system is used on motor and boat bags.

Zipper bags: There are a couple of reasons why we would put zippers on bags. However we do not do it often. One reason would be to put a different kind of closure on a mesh bag, and another like on this zippered cover over a stow bag style closure.

Figure 18 duffle bag with stow bag closure and a zipper cover over the closure

Musical instrument bags: This is an extremely broad category of dry bag. We have made dry bags in almost every one of these configurations (except Mesh) for musical instruments. Some bags are almost standard like mandolin bags, and our always popular guitar bag. Some have ethafoam for protection like my daughters trombone bag. Some are flat fold over bags like the mallet bag that serves to organize a percussionist mallets like we organize our kitchen utensils on the river. Or the cymbal bag that has foam sheets between the cymbals, and back pack straps so musicians can haul more gear in and out of the venue. Some trumpet bags have a rectangular or even a round bottom, but are made to fit the case that protects the instrument.

Figure 19 cymbal bag includes back pack straps

Figure 20 Fold over stick bag for mallet percussion mallets

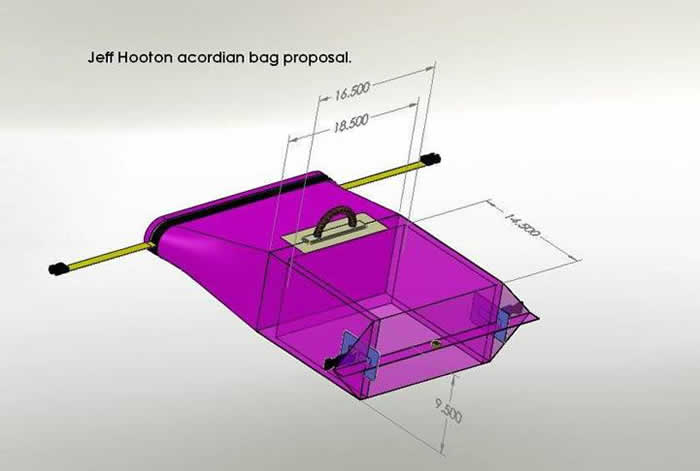

Figure 21 Acordian bag

Closures and attachments

Figure 22 Using the channel to make other attachments

This image shows how the channel can be used to add functionality to the bag by attaching it in different ways using Cam buckles. There is a heavy duty application of this system for larger load application not shown.

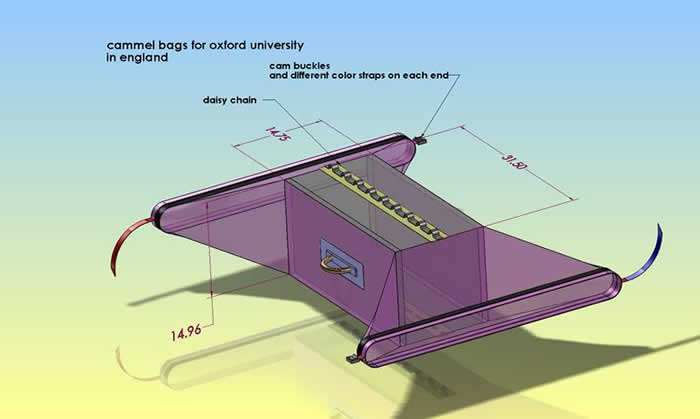

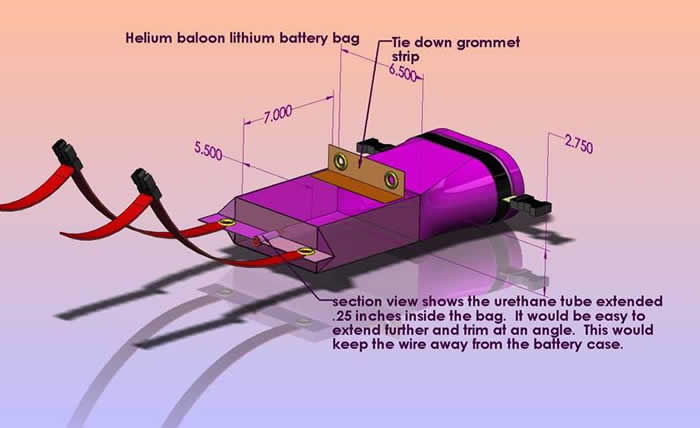

Figure 24 Daisy chain on double end duffle

Figure 25 shows a tube to allow wiring inside a roll down closure. This tube is then filled with Silicone sealant. There is also a single leg grommet strip. Single leg grommet stirps can only be pulled in 1 direction. Standard Grommet strips can be pulled in both directions.

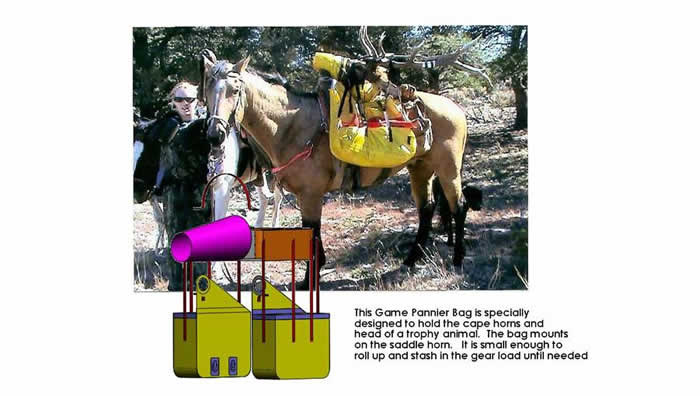

Figure 26 is a custom bag made for hauling out trophy elk. This is a very special configuration that was specified by the customer. There were many conversations, and a lot of design time.

See the custom bag table chart

See the accessories price list for some of the more common accessories we use. Others will need quotation.

home | products | pictures & information | find a dealer | river stories & testimonials | related info | FAQ | contact us

Order inquiries: shop.jpwinc@gmail.com

Custom & Prototype inquiries: pschoser.jpwinc@gmail.com

© 2011 Jack's Plastic Welding, Inc

Toll Free 1-800-742-1904

P. 505-334-8748, F. 505-334-1901